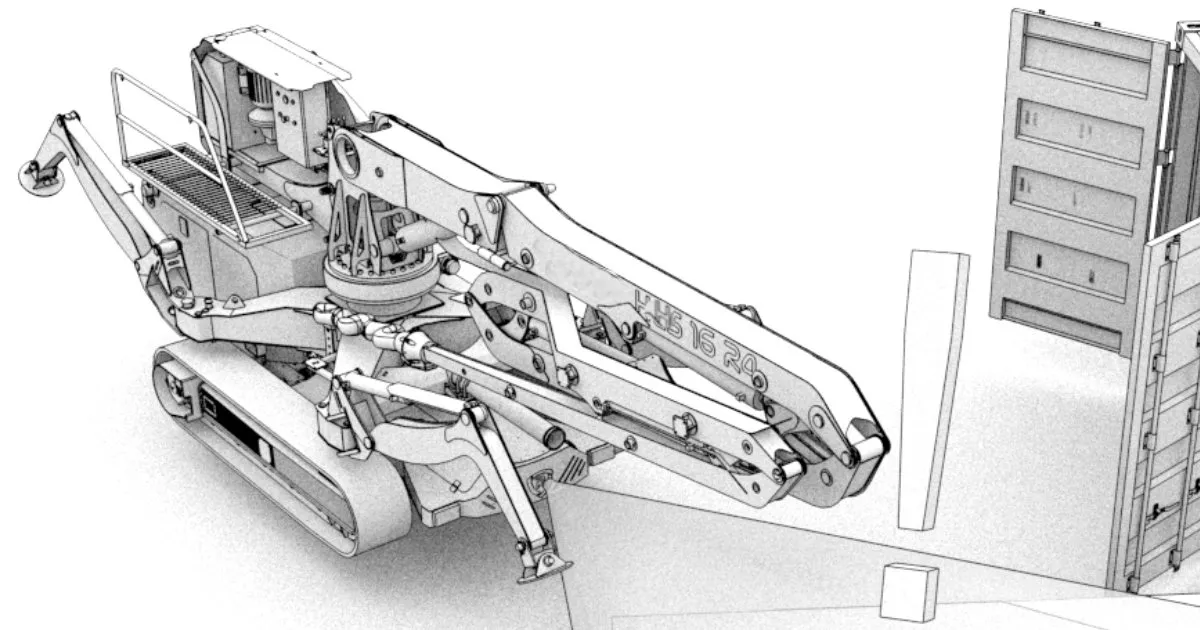

Autonomy & Planning Software Suite:

Pioneering Unmanned Construction

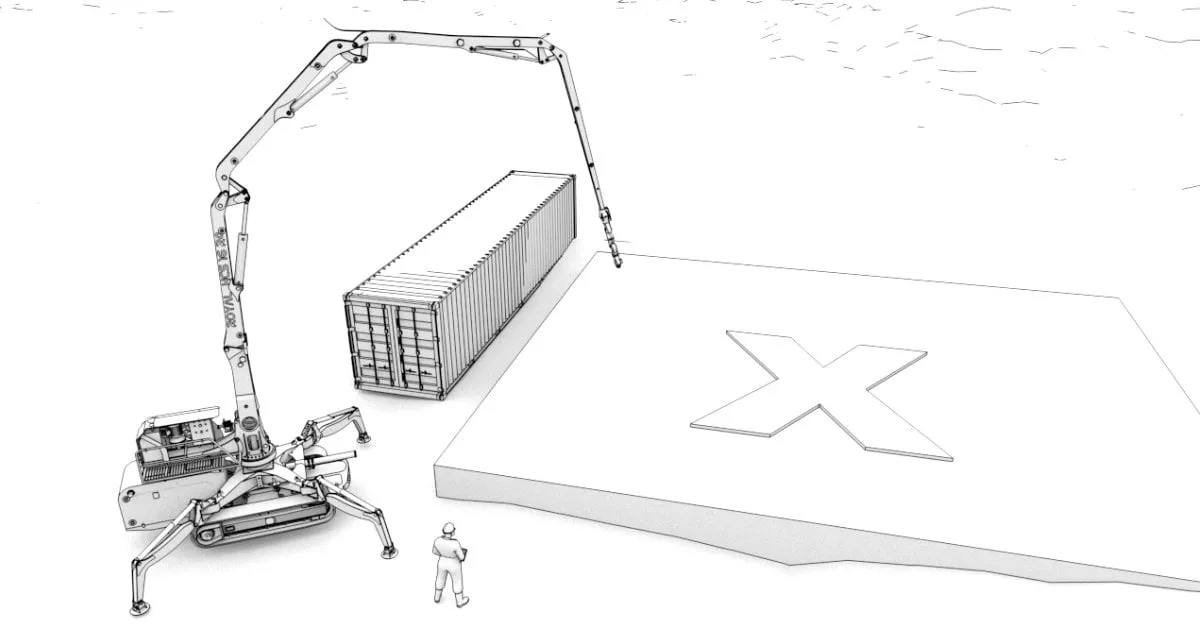

AUTOCON stands at the forefront of innovation in construction-scale 3D printing, and our Autonomy and Planning Software Suite is a testament to our commitment to efficiency, safety, and cutting-edge technology. This suite redefines unmanned construction, allowing for real-time mission planning, sensor-driven safety measures, and autonomous communication capabilities.

Real-Time Mission Planning

Our software suite enables the dynamic and real-time planning of construction missions. Whether adjusting to changes in the construction environment or responding to unforeseen challenges, the system is designed to adapt on the fly, ensuring optimal construction processes without the need for constant operator interaction.

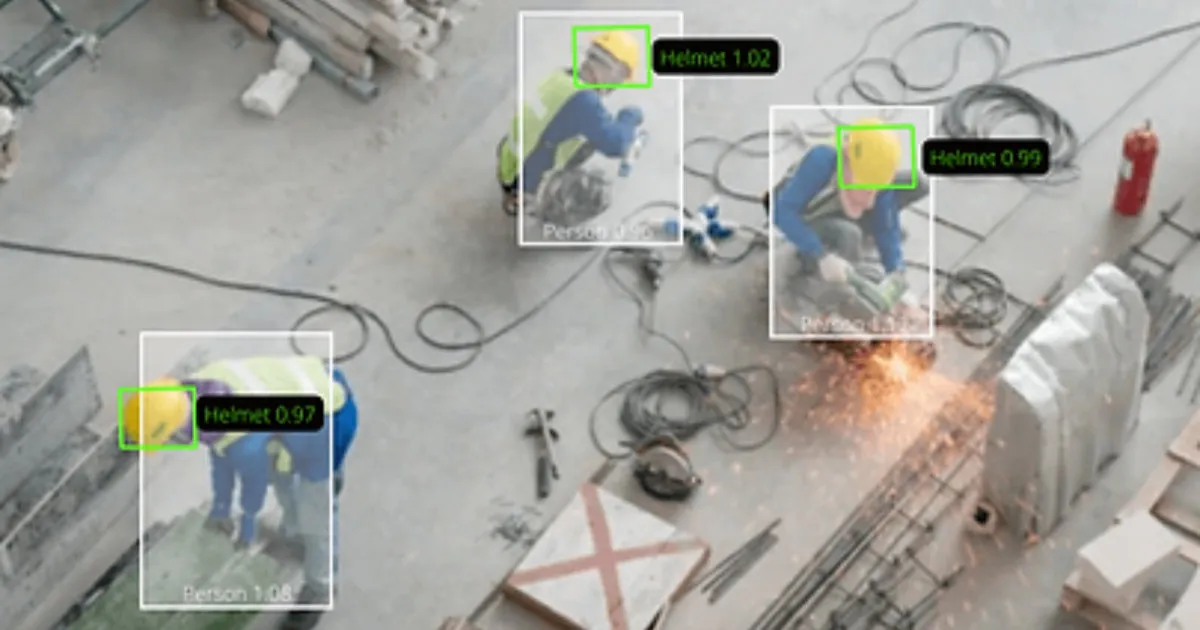

Vision-Based Vehicle Safety

Safety is paramount in construction, and AUTOCON ensures the well-being of both the technology and the construction site with vision-driven safety measures. These multi-sense-vision-systems provide real-time data to the software, allowing for the immediate identification and response to potential hazards, ensuring a secure construction environment.

Communication Support

The Autonomy and Planning Software Suite facilitates seamless communication between the various components of the construction ecosystem. This includes communication between the robotic system, sensors, and any other connected devices, creating a well-coordinated and responsive construction environment.

Unmanned Construction Efficiency

AUTOCON's software suite empowers unmanned construction by minimizing the need for constant operator interaction. This efficiency is achieved through automated planning, real-time adjustments, and adaptive responses to changing conditions, allowing for expedited building processes.

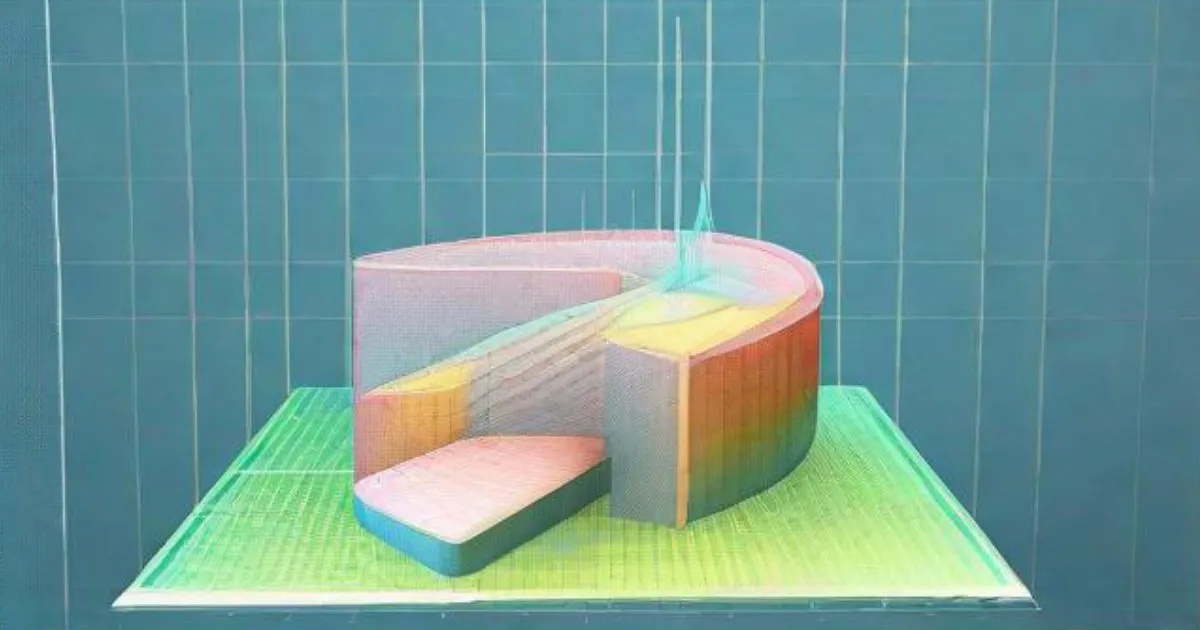

Deep Learning Approach

A cornerstone of our software is the implementation of a deep learning approach. This sophisticated method utilizes models of optimal print surfaces, a world-first explicit slicer, and "TerraSlab" mesh recognition. This ensures that the extruder's response is informed by advanced algorithms, enhancing precision and adaptability in the 3D printing process.

Models of Optimal Print Surfaces

The deep learning approach incorporates models of optimal print surfaces, allowing the system to intelligently navigate and adjust based on the specific characteristics of the construction site. This results in a more efficient and accurate construction process.

World-First Explicit Slicer

Our software suite introduces a world-first explicit slicer, a revolutionary technology that enhances the slicing process for 3D printing. This feature optimizes the interaction between the software and the extruder, ensuring each layer is precisely executed according to the design parameters.

TerraSlab Mesh Recognition

AUTOCON's deep learning approach includes "TerraSlab" mesh recognition, a cutting-edge feature that enhances the system's understanding of the construction site's topography. This ensures that the 3D printing process is adapted to the specific nuances of the terrain.

Developing New Technologies to 3D Print Buildings & Structures On-Site

Through the integration of robotics, software, and materials science, we are addressing the challenges of today's construction landscape, making it more efficient, cost-effective, and sustainable.

© AUTOCON Technologies Inc. All Rights Reserved.

Houston TX - Austin TX - Huntsville AL