Innovative Filament-Based Composite Production:

AUTOCON's Infusion Press Technology

AUTOCON's commitment to cutting-edge construction-scale 3D printing is epitomized by our revolutionary Infusion Press Technology. This innovative process seamlessly combines universal polymers with locally-sourced materials, creating a filament-based composite material that sets new standards in versatility, sustainability, and efficiency.

Fusion of Universal Polymers and Local Materials

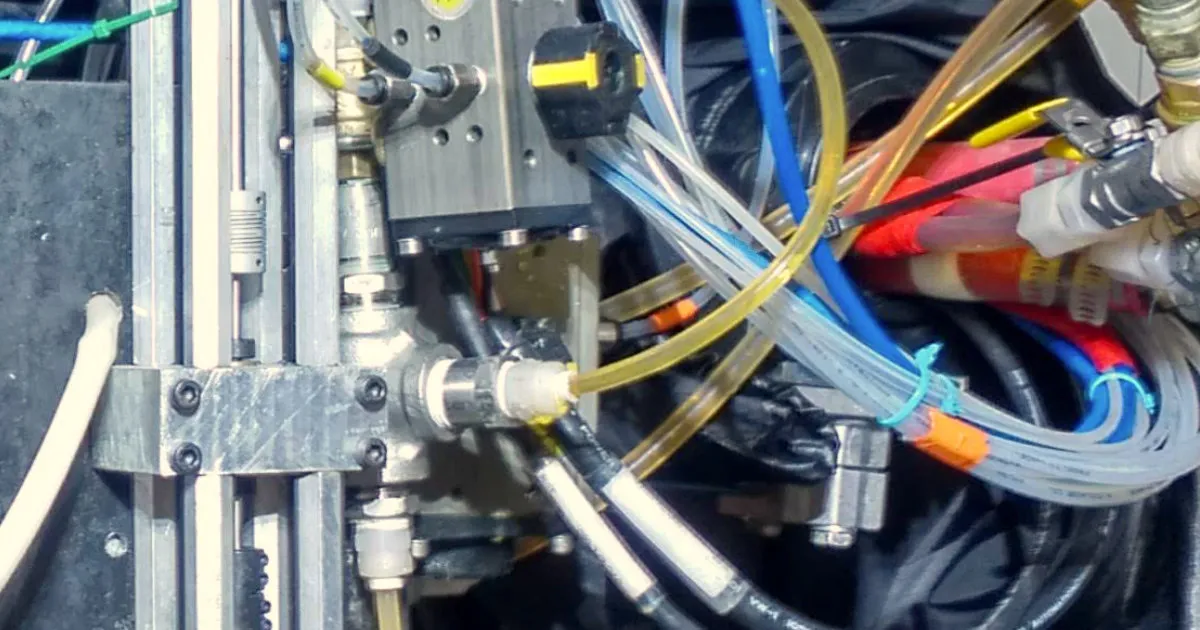

At the core of our Infusion Press Technology platform is the infusion press, a state-of-the-art apparatus that is designed to expertly blend universal polymers with locally-sourced materials. This fusion creates a composite filament that boasts the strength and adaptability of universal polymers while incorporating the sustainable and regionally-specific characteristics of indigenous materials.

Novel End Effector for 3D Printing Precision

AUTOCON's novel end effector is a game-changer in the world of construction-scale 3D printing. Positioned at the tip of the robotic arm, this specialized tool redefines precision in the 3D printing process. For more information, please contact the company.

Seamless Integration with Construction Site Dynamics

Our Infusion Press Technology seamlessly integrates into the dynamics of a construction site. The continuous extrusion and printing process, coupled with the adaptability of the filament-based composite material, contribute to a construction methodology that is both efficient and responsive to the demands of diverse projects.

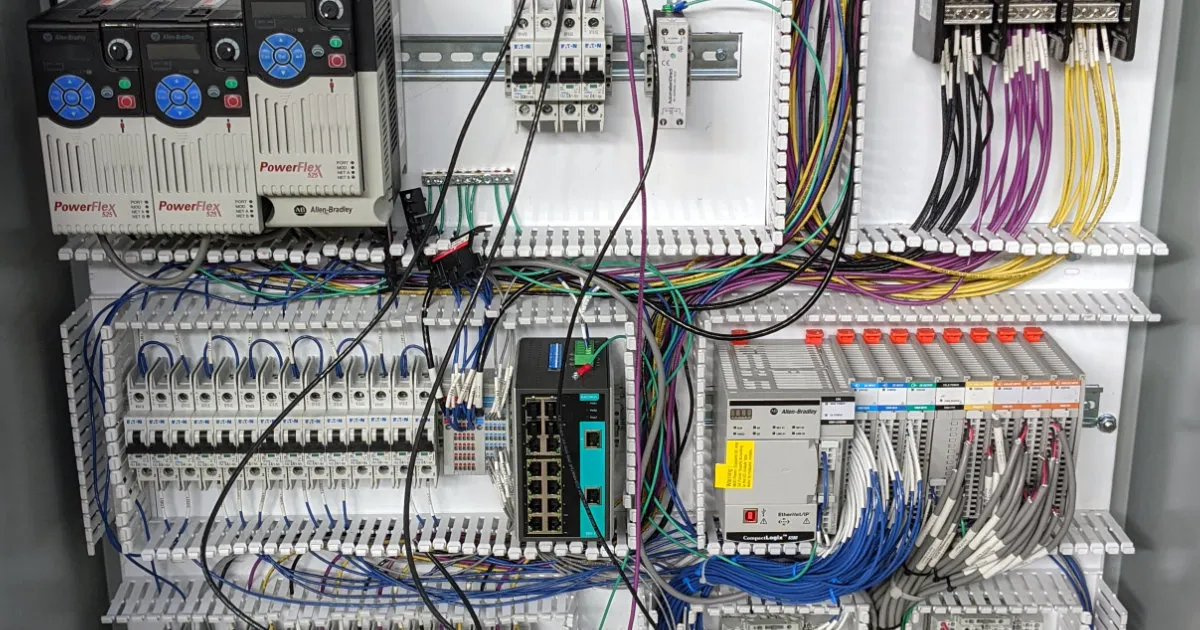

Developing New Technologies to 3D Print Buildings & Structures On-Site

Through the integration of robotics, software, and materials science, we are addressing the challenges of today's construction landscape, making it more efficient, cost-effective, and sustainable.

© AUTOCON Technologies Inc. All Rights Reserved.

Houston TX - Austin TX - Huntsville AL