Developing New Technologies To 3D Print Buildings & Structures On-Site

AUTOCON is at the forefront of transforming the construction industry by pioneering a comprehensive solution — AUTOmating CONstruction. Through the integration of robotics, software, and materials science, we are addressing the challenges of today's construction landscape, making it more efficient, cost-effective, and sustainable.

Meet Our Team:

Exceptional Expertise

At AUTOCON, we take pride in assembling a world-class team of experts, each bringing unparalleled expertise to the forefront of construction-scale 3D printing. Our team is a fusion of diverse talents, ranging from materials science and robotics/hardware engineering to software development. Together, we stand at the cutting edge of innovation in the construction industry.

Impactful Collaborations

We believe that true innovation in construction-scale 3D printing arises from collaboration and knowledge-sharing across diverse sectors. Our commitment to excellence is reflected in our strategic alliances with academia, government institutions, and private industry. These partnerships form the bedrock of our pursuit to provide the best technology for construction-scale 3D printing.

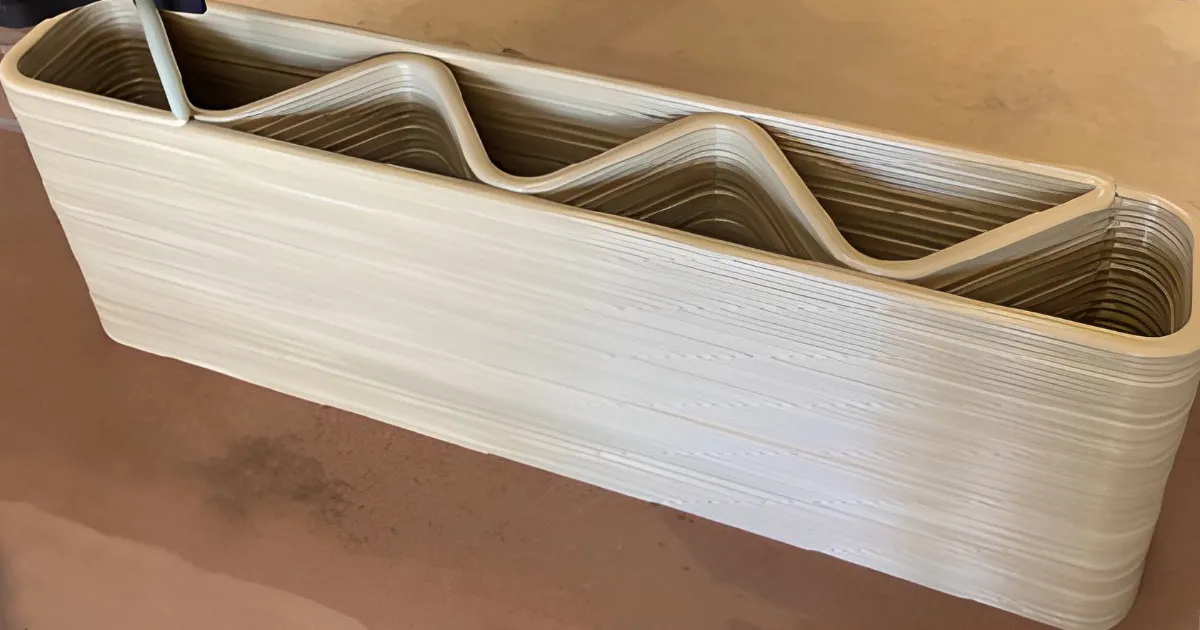

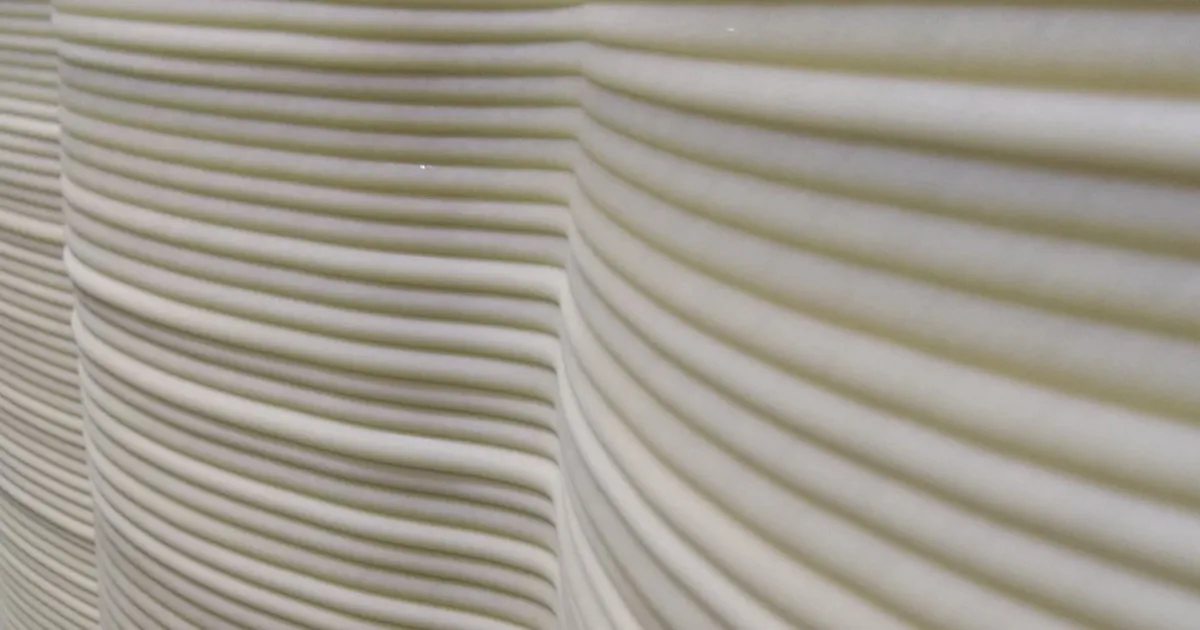

Diverse Building Materials Expertise

AUTOCON brings a wealth of experience in construction-scale 3D printing with a diverse range of building materials. Our expertise encompasses thermoplastic and thermoset polymeric systems, cementitious-based materials, geopolymers, foams, and elastomeric urethanes combined with inorganic fillers. This versatile material toolkit allows us to adapt to various project requirements and environmental conditions.

Universal Material Toolkit

Our unique material solution is based on a universal material toolkit, providing flexibility and adaptability in 3D printing buildings. This toolkit empowers us to utilize different materials based on project specifications, leveraging locally available resources globally. This not only reduces costs but also promotes low-resource manufacturing practices.

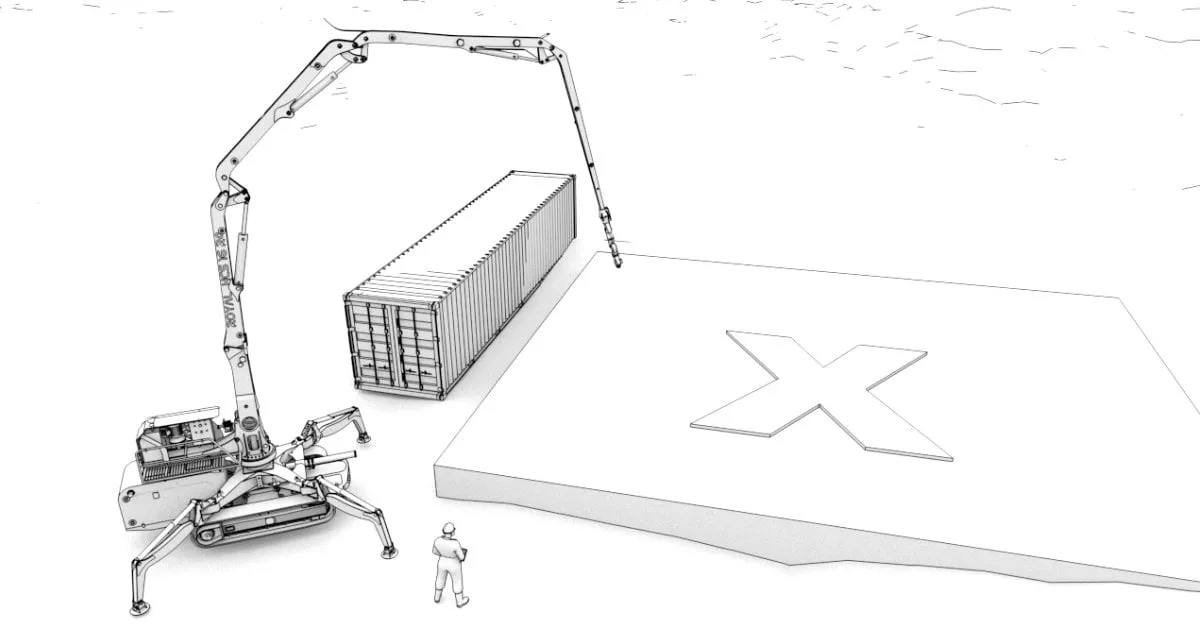

Mobile Robotic System with Vision Recognition

AUTOCON's Mobile Robotic System is a game-changer in construction-scale 3D printing. Featuring a 55-foot large-scale robotic boom arm system, it is designed to 3D print buildings and structures on-site. The system is equipped with a proprietary vision system that can recognize uneven terrains, ensuring precision and adaptability in real-world construction environments.

Low Resource Manufacturing

By utilizing locally available materials and embracing low resource manufacturing principles, AUTOCON is contributing to sustainable construction practices. This approach minimizes the environmental impact associated with material transportation and promotes the use of region-specific resources.

Efficiency and Predictability

With these innovative developments, construction processes are becoming more efficient and predictable. AUTOCON's integrated approach cuts costs and time, while simultaneously enhancing the quality of construction projects. The combination of robotics, advanced materials, and visionary software ensures a streamlined and reliable construction workflow.

Welcome To A New Era

AUTOCON's commitment to automating construction through robotics, software, and materials science is reshaping the industry. By embracing a universal material toolkit, leveraging local resources, and deploying cutting-edge robotic systems, we are not only addressing current challenges but also paving the way for a more sustainable and efficient future in construction. Welcome to the era of AUTOmated CONstruction — where innovation meets precision, sustainability, and excellence.

Developing New Technologies to 3D Print Buildings & Structures On-Site

Through the integration of robotics, software, and materials science, we are addressing the challenges of today's construction landscape, making it more efficient, cost-effective, and sustainable.

© AUTOCON Technologies Inc. All Rights Reserved.

Houston TX - Austin TX - Huntsville AL